Specification

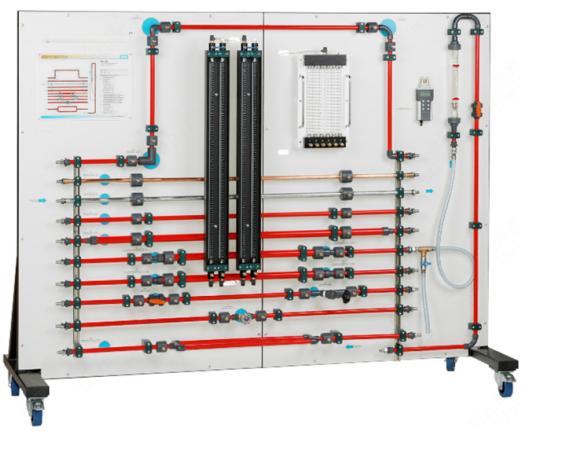

[1] simple arrangement for setting up a closed water circuit for losses in pipe elements

[2] determination of the friction head in ten different pipe sections, valves, changes in pipe direction, straight pipes, contraction/ enlargement or parallel lines

[3] Checking the relationship between pressure drop and flow velocity in the pipe and measurement of secondary load losses

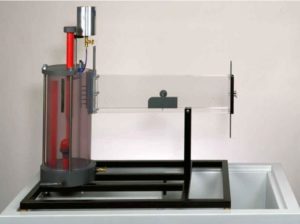

[4] plastic tank with submersible pump, flow measurement with rotameter and pressure sensor in annular chambers

[5] differential pressure measurement with differential pressure meter or

Technical Data

pump power consumption 450……600W

– head: 10…20m; flow rate: 250……200L/min -plastic Tank: 25….40L

Dimensions

Tank diameter: 300…350mm

Tank height: 500…550mm

Losses in Pipe Elements

Pipe sections length: 1000mm

– straight Cu, diameter: 17x1mm……18.5x1mm, – straight galvanised steel, diameter:1/2…3/4″

– straight PVC, diameter: 18…24×1.5mm,

– straight PVC, diameter: 30…35×1.5mm

– section with segment bend, elbow, pipe bend

– gradual/sudden enlargement in dia.: from 20 to 35mm – gradual/sudden contraction in dia.: from 35 to 20mm – dual line, PVC, diameter: 18…22×1.5mm

Reviews

There are no reviews yet.