TEMPERATURE PROCESS TRAINING SYSTEM

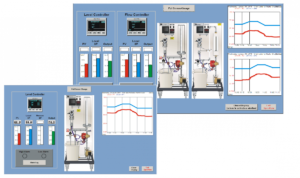

The Temperature Process Training System is a compact and mobile unit for a wide range of experiments in temperature control. It gives students a greater understanding of the stability of simple control systems. The self-contained unit can do many experiments, but it can also connect to the optional Computer Control System (TE3300/06) for distributed control.

The main parts of the Temperature Process Training system are:

- Industrial controller with autotune feature

- Two-channel chart recorder

- Heat-exchanger and fan

- Temperature transmitter

- Thermocouples

- Delay coil

- In-line heater

- Three-speed pump

- Reservoir

To perform experiments, students fill the reservoir with clean water and prime the system. They then set the controller to regulate the power to the in-line heater and control the temperature of the water at any of three places. The heat-exchanger removes the heat from the water, to give quicker experiments. The thermocouples (selected by a three-way switch) give feedback to the controller.

For a realistic experience, the equipment has industrial standard instrumentation and parts.

The apparatus includes one gate valve that works as a flow bypass. A chart recorder shows and logs the changes of the process variable (temperature) and the controller output.

LEARNING OUTCOMES

- Proportional, integral and derivative control

- Setting up and demonstrating automatic control

- The principles of loop control and the calibration and tuning of temperature transmitters and thermocouples

- Operation of a temperature control system

- Distributed control (when used with the TE3300/06 Computer Control System)

Reviews

There are no reviews yet.